RIR-MAPLE: What is it?

Resonant Infrared Matrix-Assisted Pulsed Laser Evaporation (RIR-MAPLE) is a technique that enables us to create high-quality films while maintaining fine control over the resulting material's bulk properties. A derivative of Pulsed Laser Deposition, bursts of laser energy are used to evaporate particles from the frozen solution inside a liquid nitrogen cooled crucible (target). This frozen solution is composed of various solvents together with the individual components of the material we wish to create. Characteristic bonds in this mixture absorb the radiation and evaporate, freeing the embedded particles we want to build our materials from. A 'cloud' of precursor materials then resides in the vacuum chamber together with our desired substrate where they will ultimately rest upon.

RIR-MAPLE: Versatile

RIR-MAPLE has demonstrated the ability to create films out of these components on a variety substrates. In our work with RIR-MAPLE, the precursor mixture is usually composed of both polymer chains (organic) and nanoparticles (inorganic), enabling us to create hybrid organic-inorganic materials. Previously, synthesis of such materials was heavily dependent on chemical interactions between the components and their respective solvents. Solution-based processing/deposition methods (spincoating, doctor blading, inkjet, etc) required that specific reactions be prevented or encouraged while maintaining compatibility with all other components or processes specific to the device. RIR-MAPLE lessens chemical incompatibility worries by providing a purely physical method of deposition where no solvents contact the substrate (a 'dry' process). Being able to do so on our choice of substrates, independently of any chemical interactions, is something very unique about this system.

RIR-MAPLE: Lower Energy

Another unique characteristic of our system is the use of an Er:YAG laser instead of the UV types that characterized our system's predecessor (UV-MAPLE). Er:YAG lasers emit short infrared radiation with wavelengths around 3 μm, which are strongly absorbed by any hydroxyl (O-H) bonds in our solution. Water and phenol are precisely chosen to be in our solution due to the presence of these bonds in their chemical structure. These bonds are known to be resonant with short infrared radiation like that of our chosen laser, leading to the high absorption of energy and subsequent evaporation of the solvent. This mechanism is responsible for transforming electromagnetic energy into thermal energy and gives rise to our Resonant Infrared (RIR) variant of the MAPLE system. Presence of these bonds in the matrix1 surrounding our target precursors also refer back to the Matrix-Assisted part of this Pulsed Laser system.

RIR-MAPLE: Emulsion Based Approach

The biggest benefit that comes from the matrix assistance and use of resonant infrared radiation can be observed when considering the implications of working with organic components and laser energy. Highly focused bursts of UV energy can be enough to 'cut' the long chains of monomers that make up our organic components. This leads directly to polymer degradation and the alteration of our material's properties. In contrast, short infrared radiation has a relatively low risk of interacting with organic components in our water based emulsions, specifically targeting the assisting matrix. Having the peace of mind that our polymers stand safely against the highly focused radiation emitted from a laser is essential in allowing us to continue utilizing our system without fear of non-idealities.

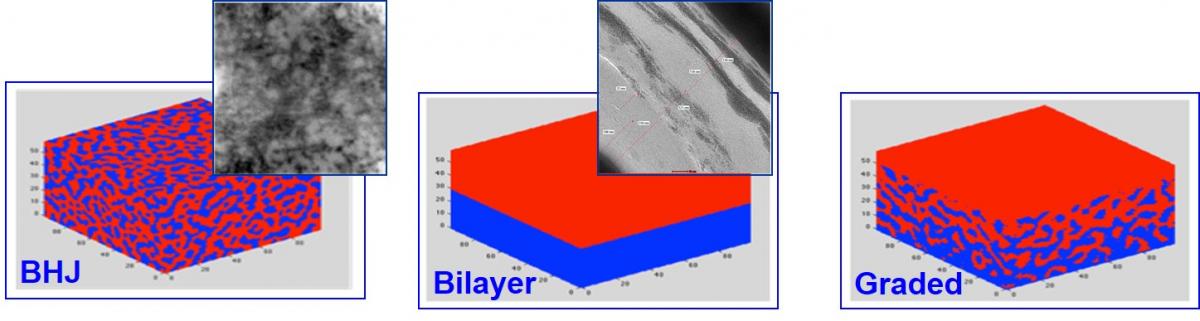

RIR-MAPLE: Control

Something retained from UV-MAPLE is the ability to control the resulting material's composition very precisely. Once deposition rates are known for the different components that are to be deposited, we can control how much of each component is deposited. By choosing how much time the laser spends on each partition of our target (known as 'dwell time'), we effectively control how much of each component is released and then reaches the substrate at a given time. Changing this in a time-dependent manner allows us to give our materials certain types of structures. With these structures comes the possibility of them having unique properties we can harness (i.e. gradient photovoltaics), or to guarantee equal distribution through the material to form a bulk heterojunction.

RIR-MAPLE: Future Possibilities

With all of RIR-MAPLE's abilities, what is left to do is see how we can apply these to create novel, competitive (opto)electronic hybrid devices. Past work has shown the ability to create a variety of materials and devices, and current work should provide insights on the capability to create OLEDs, hybrid photovoltaic cells, medical sensors, and mid-infrared detectors.

Authored by E. Tomas Barraza. For more visit tomasbar.com

1 matrix: an environment or material in which something develops; a surrounding medium or structure

Photo credit: Medical Design Technology Magazine

This work is licensed under a Creative Commons Attribution 4.0 International License.